If your COGM is higher than your selling price, then you aren’t making a profit on each item sold — and this can be bad news for your business. If you don’t know how much COGM you have, you won’t be able to make informed decisions about pricing or product development. Your profitability depends on identifying all sources of costs, and your inventory is the core part of your costs. You can stay on top of your costs by understanding, measuring, and tracking COGM. The cost of goods manufactured (COGM) is an important metric, especially for manufacturing businesses, because it can affect profitability, which is the ultimate goal of any business. Once all relevant ledger account data is captured and allocated, the software automatically calculates the total cost of goods manufactured for each production order or batch by applying the COGM formula.

FAQ: Unlocking Insights into COGM

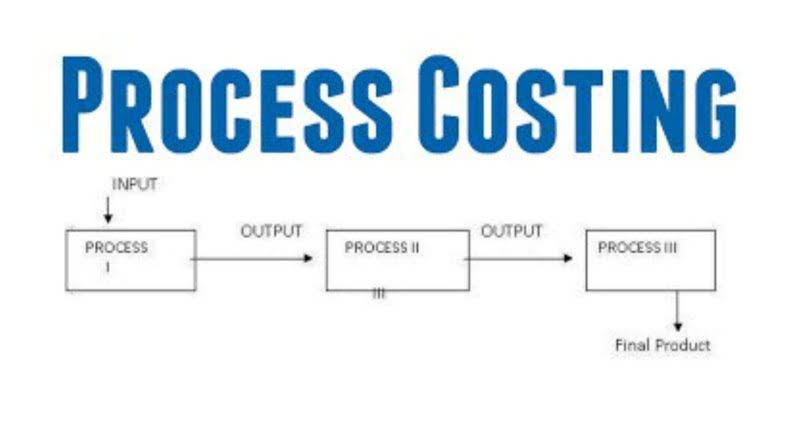

The COGM schedule is a part of the financial statement of a business that shows the total cost incurred by a company to manufacture goods during a specific period, typically a month or a year. COGM is used in the income statement of the reporting and is subtracted from sales to then calculate gross margin (the portion of a company’s revenue after direct costs have been removed). Understanding the cost of goods manufactured (COGM) is essential for any manufacturing business. This concept helps businesses track the total expenses involved in producing goods, which is vital for managing profitability and making informed decisions. This guide will walk you through the calculation of COGM, its components, and its significance in financial reporting. As we have seen, the total manufacturing cost and cost of goods manufactured are very similar metrics.

Use Fewer Materials

It helps you see how much it costs to create your goods, which is important for making smart financial choices. Remember, COGM includes all the costs of making your products, like materials, labor, and overhead. Keeping track of these costs can help you manage your business better and ensure you are on the right path to success.

The cost of goods manufactured formula

Direct materials, such as steel used to construct automobile frames or fabric in clothing manufacturing, may be easily linked to a particular product or unit of production. Say, a furniture manufacturer has $100 in stock of materials at the start of the period. When we input the numbers in this example into the cost of goods manufactured formula, we get $1145.

Direct material costs include the expenses for raw https://www.bookstime.com/ materials used directly in manufacturing products. To find this, add the beginning inventory of raw materials to the purchases made during the period, then subtract the ending inventory of raw materials. Indirect materials are supplies used in the production process, but that cannot be directly linked to a particular good or production unit.

- It’s easier to show rather than tell, so let’s pretend you run a bakery.

- This information is essential for companies to stay competitive in today’s marketplace.

- Cost of goods manufactured (COGM) is a term used in accounting to describe the total cost of manufacturing goods during a specified period.

- Businesses run on many things—time, money, inventory, supply lines, opportunity, and so on.

- All manufacturing businesses should use the cost of goods manufactured (COGM) to track and understand production costs.

Can COGM be used for service businesses?

Total manufacturing cost, a.k.a total cost of production, is a KPI that expresses the total cost of manufacturing, e.g., all activities directly tied to the production of goods during a financial period. It’s very similar to the cost of goods manufactured except that it doesn’t factor in work in process. While COGM measures the cost of producing goods, COGS reflects the cost of goods actually sold during a specific period. COGM is crucial to many important business decisions, such as pricing, product design, and resource allocation.

What about cost of goods sold?

Investing in technology and automation can streamline production processes, reduce labor costs, and minimize errors. Modern manufacturing technologies such as robotics, IoT (Internet of Things), and AI (Artificial Intelligence) can enhance productivity and efficiency. For instance, automated assembly lines can improve throughput and consistency while requiring fewer manual interventions. Direct materials encompass the raw cost of goods manufactured calculator materials and components that directly contribute to the production of goods. These materials are transformed during the manufacturing process into the finished product. Examples include metals, plastics, electronic components, and any other materials that are integral to the final product’s composition.

- This table is designed to provide quick references and facilitate a better understanding without the need for complex calculations.

- COGM is calculated by adding up these costs and adjusting for the beginning and ending work in process inventory.

- In spite of the similarities in the names, the cost of goods manufactured (COGM) is not interchangeable with the cost of goods sold (COGS).

- The cost of goods manufactured in the total production cost of goods produced and completed by the company during an accounting period.

- An increase in COGM can suggest rising production costs or inefficiencies.

- Our site is jam-packed with the strategies, tactics, and tools that entrepreneurs, employees, and consumers are using to succeed.

- Lean manufacturing principles aim to eliminate waste, optimize processes, and improve efficiency, thereby reducing overall manufacturing costs and enhancing competitiveness.

- Factory overheads are part of the total manufacturing costs and affect the COGM by adding to the total cost of production.

- Another similar phrase to cost of goods manufactured is cost of goods sold.

- The main components of COGM are direct materials, direct labor, and manufacturing overhead.

This represents the total cost incurred by the company to produce the mountain bikes during that month. For now, though, keep in mind that WIP inventory refers to products that have yet to complete the production cycle and are not ready to be sold to customers. The (COGS) is an essential component that provides a clear picture to business owners and managers about the company’s manufacturing performance. You can calculate Direct materials by adding the beginning raw materials to the purchases made and subtracting that total from the ending raw materials. Direct materials refer to all the raw materials used to produce the finished product or in its final form. There was this one company that started using automated machines to do the work of three people.

Cost of Goods Manufactured (COGM) is the total production cost of goods completed during an accounting period. COGM is a critical component of profit and loss statements and measures the cost of producing and selling a product. By comparing the COGM to the revenue generated from selling the product, a company can determine its gross profit margin and assess its financial performance. When AMD sells finished goods, the cost of these goods is transferred out of finished goods inventory into the cost of goods sold account, which this company calls cost of sales, as many companies do. The operating portion of AMD’s income statement follows—again, all amounts are in millions.